As a result of long-term research and trial and error regarding the production of placenta raw materials, CHARITES LAB has established a unique placenta production technology.

Its biggest feature is that it uses new manufacturing processes such as “protein decomposition using a special enzymatic digester”, “ultra high pressure extraction, and “high pressure aging” to achieve the ultimate in atomization, slight odor, and aging. We have received high praise as a raw material for cosmetics.

INDEX

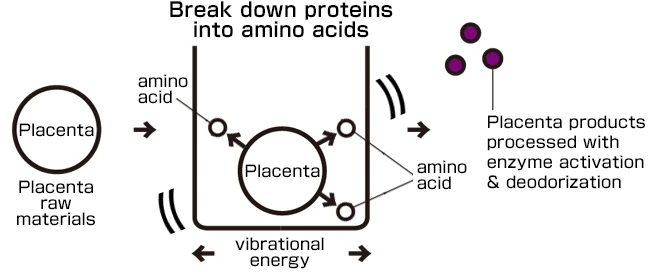

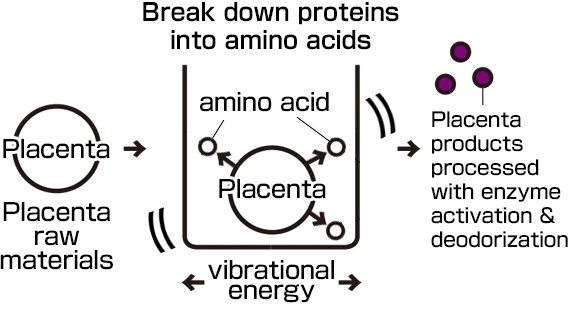

Placenta protein degradation

Realizes more efficient protein decomposition and lower odor

The placenta, which is the raw material for placenta, is subjected to protein decomposition using an enzymatic digestion kettle (for food or cosmetics). This is an important process in producing placenta raw materials, as it breaks down protein, the main component of placenta, down to the amino acid level.

Vibration energy is applied to the enzymatic digestion kettle using our own equipment. This activates enzyme activity, shortens heating time, and reduces residue. In other words, nutrients can be efficiently converted into placenta raw materials from the placenta. In addition, by shortening the heating time, it is possible to fundamentally reduce the occurrence of the unique “odor” of placenta. (Compared with an enzymatic digestion kettle that does not apply vibrational energy)

Enzyme digestion pot 1

Enzyme digestion pot 2

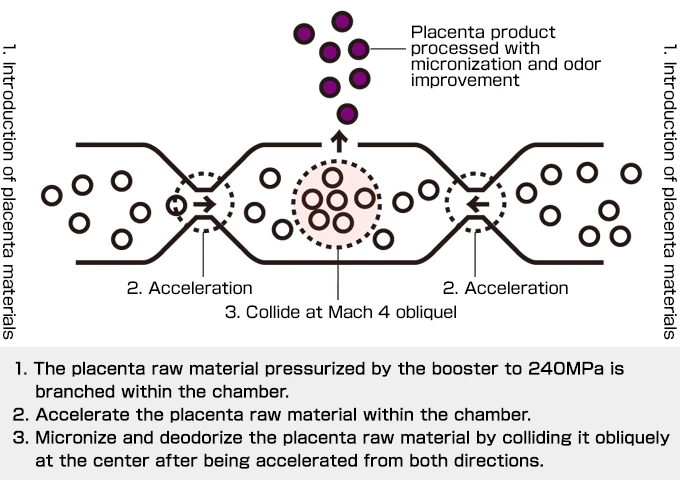

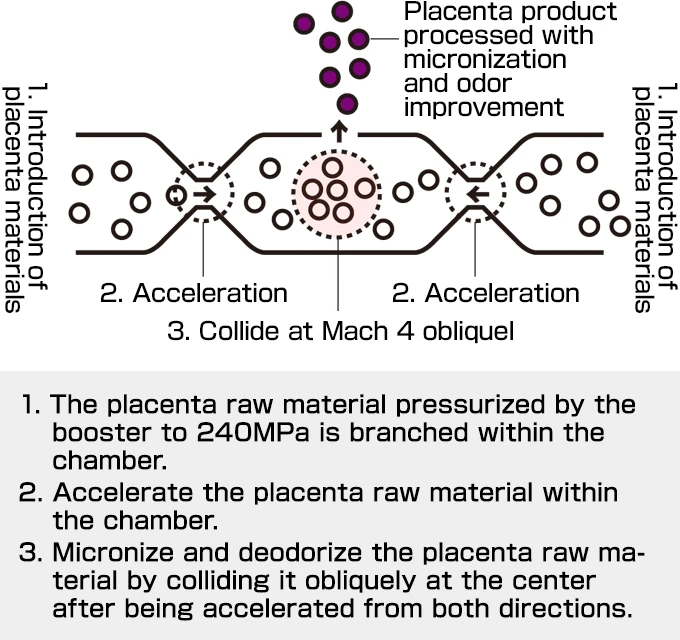

Placenta ultra-high pressure extraction

Succeeded in ultra-high pressure extraction of 245Mpa (megapascals)

The placenta material, whose proteins have been decomposed in an “enzyme digestion pot,” is extracted using an ultra-high pressure extraction machine.

Inside the ultra-high pressure extraction machine, the placenta raw materials (particles) are collided obliquely at a relative speed of Mach 4 under a high pressure of 245Mpa (megapascals) to “atomize” them (nanization). The atomization of placenta particles has made it possible to dramatically reduce “placenta odor,” and its viscosity is low even at high concentrations, greatly expanding the range of applications for products.

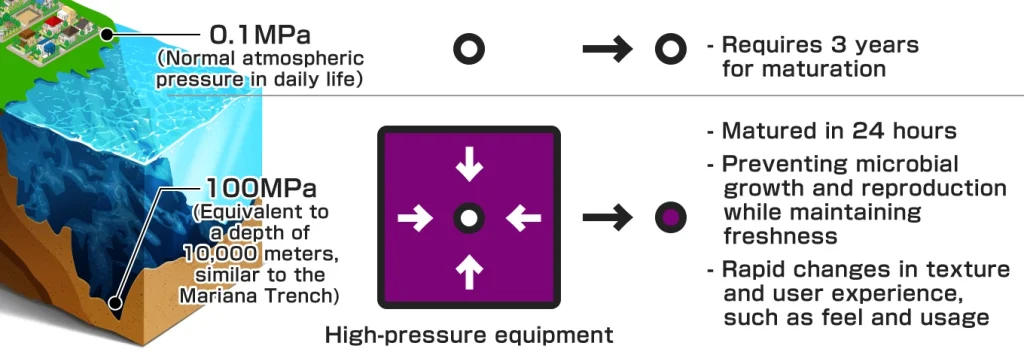

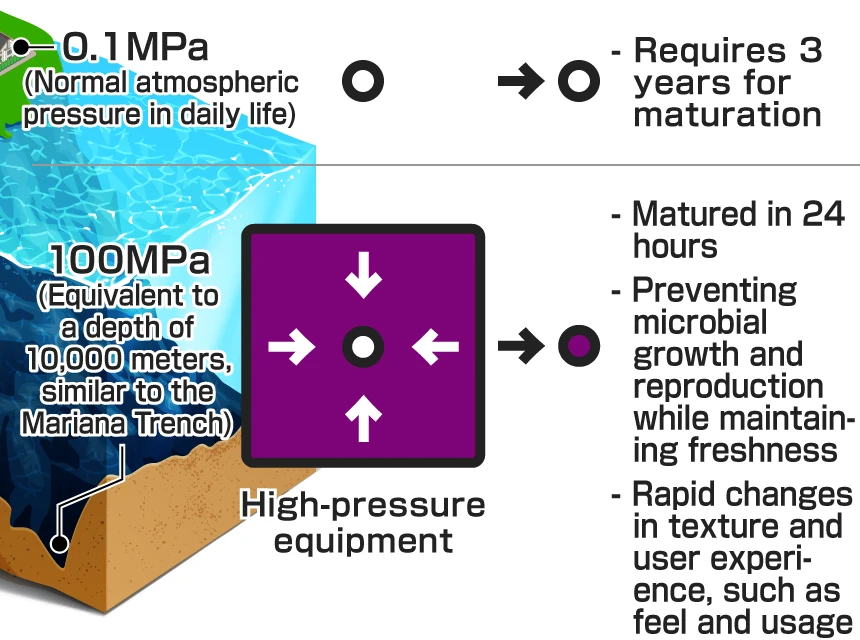

Placenta high pressure aging

Aging in a 100Mpa high pressure cooker

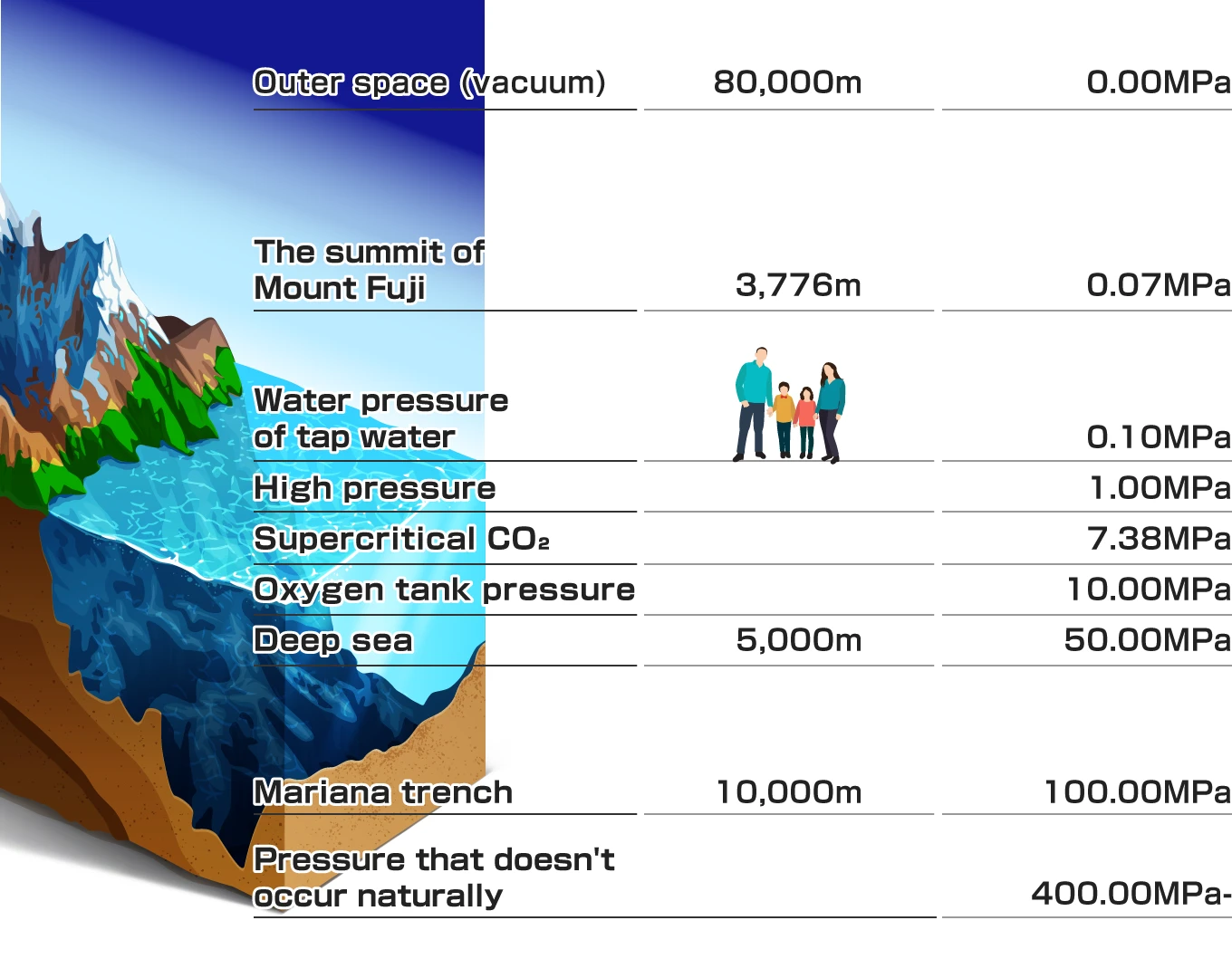

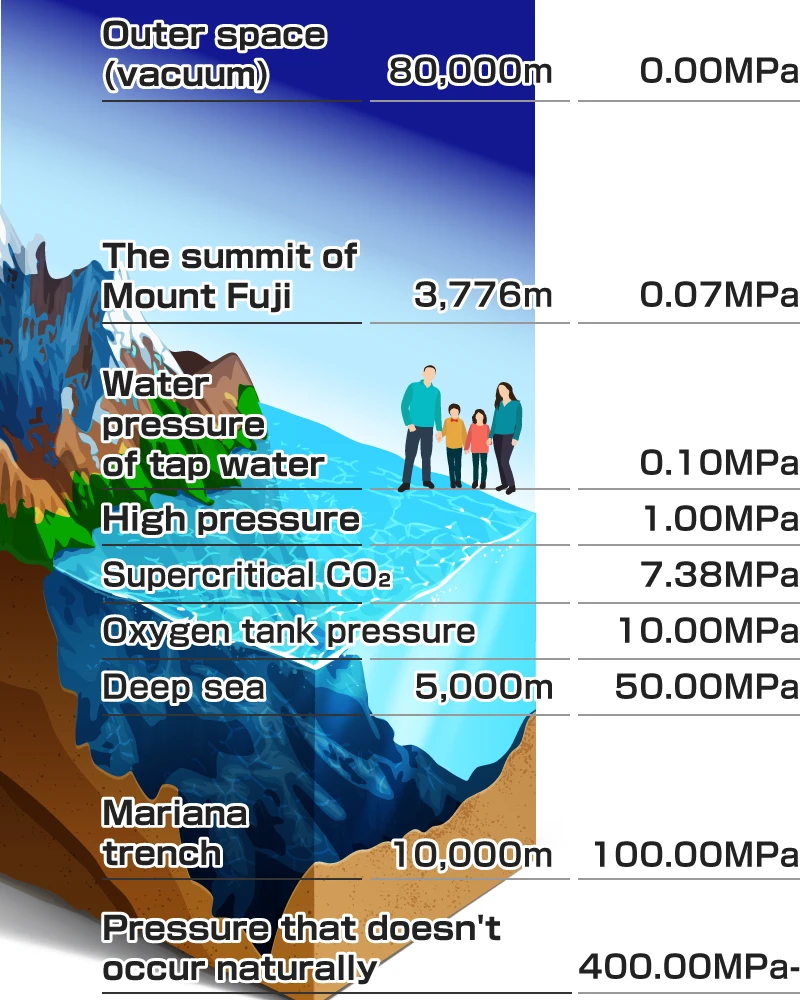

This is a system that applies high-pressure processing to raw materials, and is capable of applying pressure equal to 100 MPa (megapascals) to products, equivalent to the Mariana Trench (10,000 meters deep), which is said to be the deepest in the world.

By subjecting placenta raw materials to an ultra-high pressure 100Mpa (1,000 atm) high-pressure cooker for 24 hours, we produce a product that is equivalent to raw materials that have been naturally aged for 3 years at normal pressure (the environment in which we usually live, where 1 atm = 0.1 MPa). It will be finished into something.

Because it is aged in a short period of 24 hours, it is possible to maintain freshness and prevent the growth and proliferation of microorganisms.

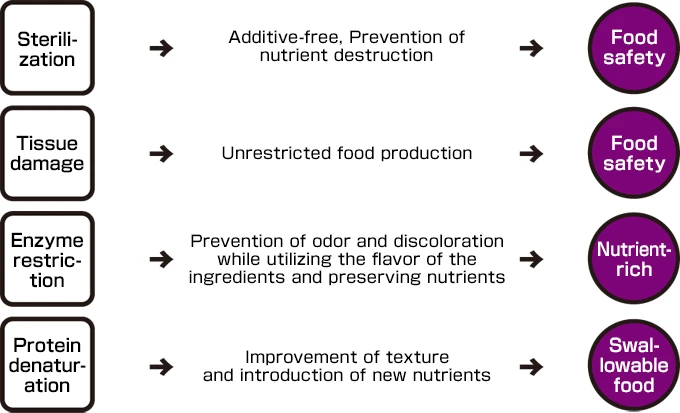

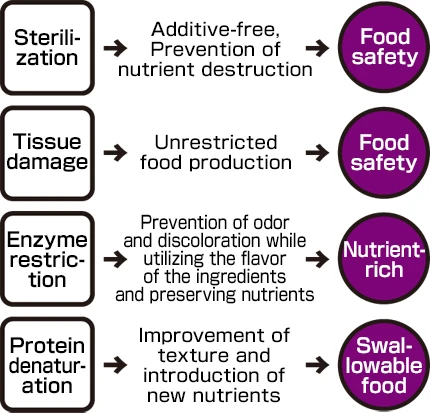

What happens when high pressure is applied?

When pressure is applied to a substance inside a sealed container, the molecular density increases. As the density increases, molecules collide more often with each other and with walls. The more molecules collide, the more the pressure increases, and the more molecules collide with each other, the more molecules collide with each other, and when this is amplified, the molecules will fly off in all directions. This manifests itself in the strength of its spreading power. Specifically, applying high pressure treatment to placenta raw materials can bring about the following effects.

Aging of placenta raw materials

By applying a pressure of 100 MPs (megapascals) to the placenta raw material for 24 hours, the result is a raw material that is equivalent to natural aging for 3 years.

Preventing deterioration of placenta raw materials

By applying high pressure, we prevent the growth and reproduction of microorganisms while maintaining freshness. It becomes less susceptible to so-called corrosion.

Miniaturization of placenta particles

By applying pressure, they become smaller than normal placenta particles, and after release, they return to their original size over time. When this property is used in cosmetics, etc., there are dramatic changes in the texture and feel of the product.

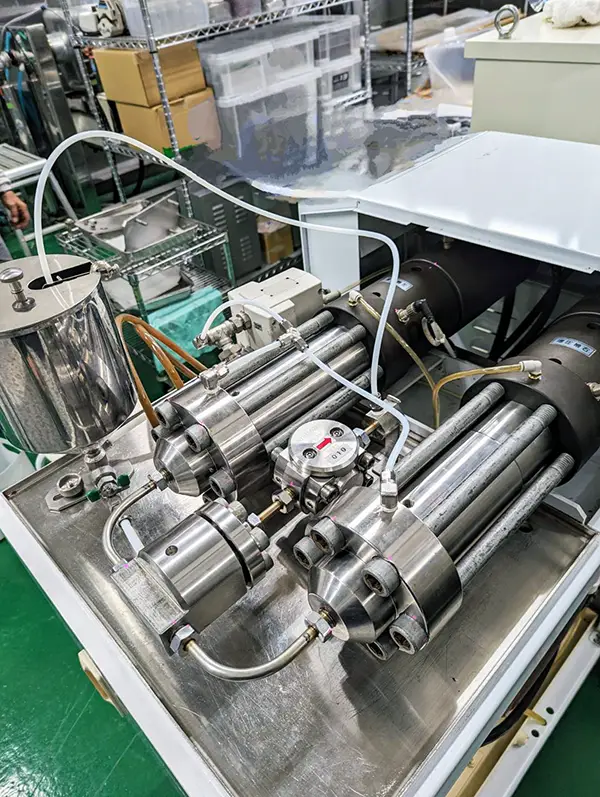

Automatic high pressure processing equipment

Nanomizer (Starburst)

Automatic high pressure processing equipment

Inside of automatic high pressure processing equipment

Inside of automatic high pressure processing equipment

What is high pressure?

The environment in which we normally live is approximately 1 atmosphere (approximately 0.1 MPa (megapascal)) or 1000 hPa (hestopascal). High pressure refers to pressures of 1 atmosphere or more, and past research has confirmed that applying pressure can bring about various changes in substances. In fact, when high pressures of 100 MPa or more are applied, changes in substances become noticeable. (100MPa is the same pressure as the Mariana Trench, which is said to be the deepest in the world.) Also, by applying strong pressures of 100MPa, 400MPa, and 600MPa, it is possible to see denaturation of materials that would not normally occur. Masu.

Synthetic diamonds, which have had a major impact on global industry, are products of this high-pressure technology. CHARITES LAB, we apply high-pressure treatment to the products produced in our own factory to create high-quality products.

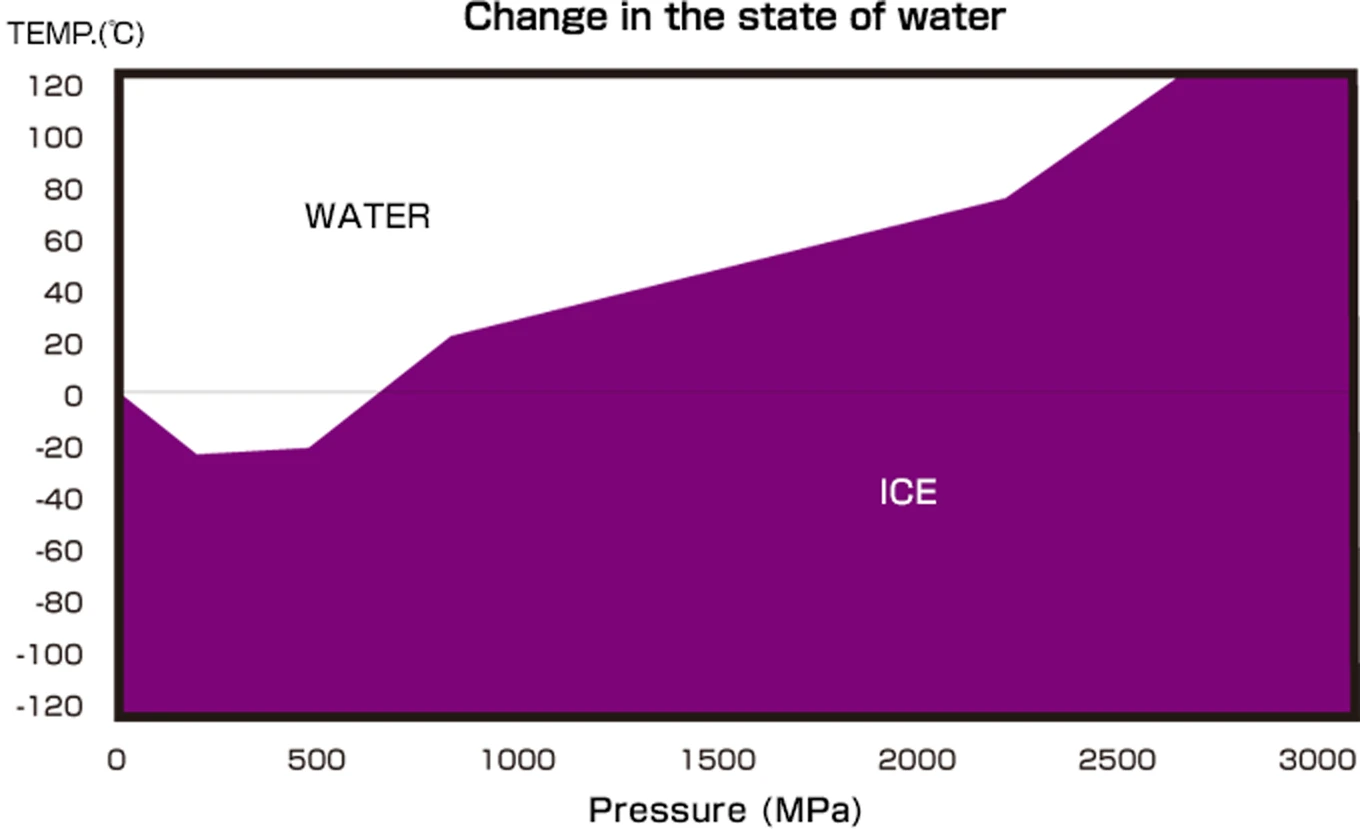

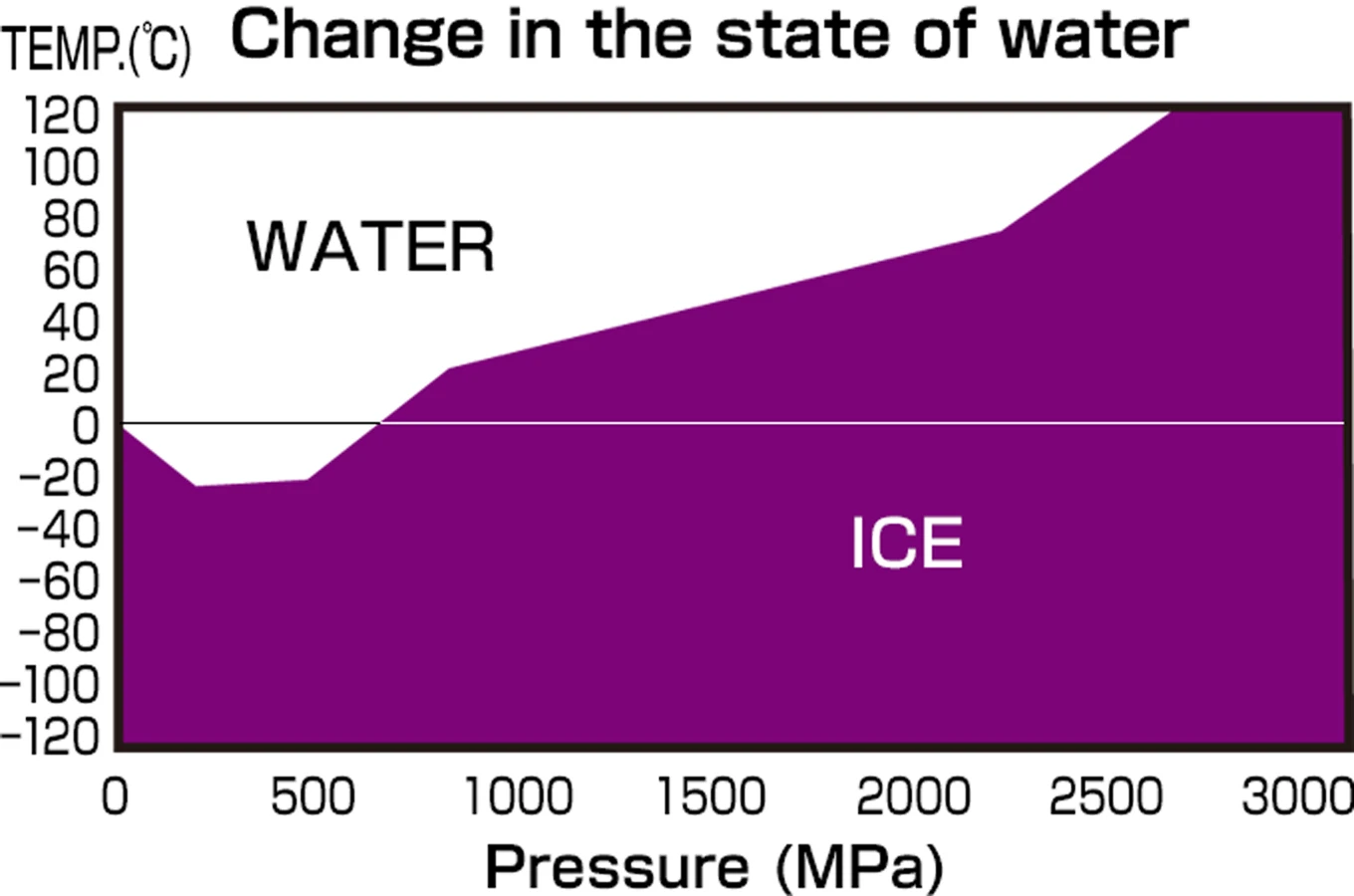

Changes in substances during high pressure treatment

Water normally turns into ice at 0°C, but if you apply a pressure of 1500 MPa to heated water, polycrystalline ice forms. Furthermore, under a pressure of 2300MPa, even boiled water turns into ice. Furthermore, even at -20℃ or below, it becomes water under a pressure of 200MPa.

High pressure treatment instead of fire

In a modern society that places importance on health, cooked and processed foods are required to have minimal processing, no additives, high storage stability, high quality, and high nutritional value. Humans have been using the heat obtained from fire to cook and process food for about 1 million years. However, when foods are heated, chemical reactions occur, such as functional groups in molecules reacting with other functional groups to form heating products or useful ingredients disappear. To put it simply, while food production and processing that uses heat is superior in terms of preservation and hygiene, it also results in a loss of freshness, flavor, and nutrients from the ingredients.

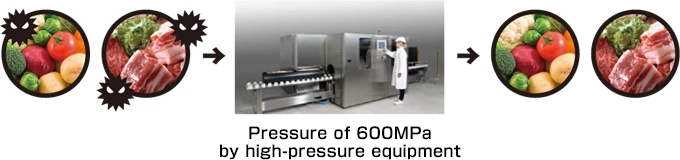

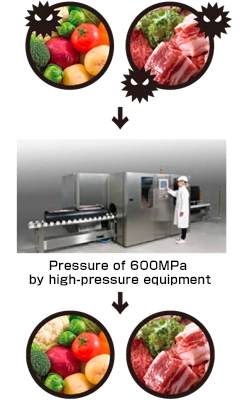

By performing high-pressure processing, it is possible to denature (change the properties of) proteins and starches, and because there is no formation or cleavage of chemical bonds, the ingredients, aroma, color, and freshness of the ingredients are maintained. . It also inactivates (sterilizes) microorganisms such as E. coli, Sammonella, and Staphylococcus, making it possible to perform highly functional food processing that cannot be achieved with heat.

Non-heat sterilization by high pressure treatment

By applying ultra-high pressure to food, bacteria, viruses, etc. are killed. It also reduces enzyme activity, which increases flavor, texture, and nutrients. This can be called an epoch-making food processing method that fundamentally overturns food preparation methods in human history.

Beef liver was inoculated with bacteria such as E. coli, Salmonella enterica, and Staphylococcus aureus, and after being treated at each pressure, the number of remaining bacteria was measured. When the number of bacteria was 105 to 107 CFU/, E. coli and Salmonella were no longer detected after treatment at 300 MPa for 90 minutes, 400 MPa for 60 minutes, and 500 MPa for 30 minutes, and Staphylococcus aureus was no longer detected after treatment at 600 MPa for 30 minutes.

Salmonella

| Pressure (MPa) | Time (minutes) | Viable bacterial count (CFU/g) |

| 0 (before precessing) | 1.0×103 | |

| 300 | 30 | 2.1×103 |

| 300 | 30 (5 minutes 6 times) | Not detected |

| 300 | 60 | 2.0×103 |

| 300 | 90 | Not detected |

| 0 (before precessing) | 9.0×103 | |

| 400 | 30 | 2.5×103 |

| 400 | 60 | Not detected |

| 0 (before precessing) | 1.0×103 | |

| 500 | 30 | Not detected |

Staphylococcus aureus

| Pressure (MPa) | Time (minutes) | Viable bacterial count (CFU/g) |

| 0 (before precessing) | 1.0×103 | |

| 300 | 30 (5 minutes 6 times) | 6.8×103 |

| 300 | 90 | 1.2×103 |

| 0 (before precessing) | 1.4×103 | |

| 400 | 60 | 1.0×103 |

| 0 (before precessing) | 1.4×103 | |

| 600 | 30 | Not detected |

Escherichia coli

| Pressure (MPa) | Time (minutes) | Viable bacterial count (CFU/g) |

| 0 (before precessing) | 2.5×103 | |

| 300 | 30 | 5.0×103 |

| 300 | 30 (5 minutes 6 times) | Not detected |

| 300 | 60 | 4.5×103 |

| 300 | 90 | Not detected |

| 0 (before precessing) | 7.5×103 | |

| 400 | 30 | 2.0×103 |

| 400 | 60 | Not detected |

| 0 (before precessing) | 1.2×103 | |

| 500 | 30 | Not detected |

Cosmetic production using silk fibroin

Silk fibroin emulsification method – new emulsification technology that does not use surfactants

Traditionally, surfactants were required to emulsify cosmetics, but with this technology, it is now possible to emulsify creams and emulsions without using any surfactants.

What is silk fibroin?

There are two types of proteins that make up silk: sericin and fibroin.

Silk fibroin is made from only fibroin.

Characteristics of silk fibroin

- Contains 18 types of amino acids, 9 of which are “essential amino acids” that cannot be synthesized by the body

- Easily blends into the skin as it has a similar composition to that of human skin and body

- Although it is a naturally derived ingredient, it has excellent emulsifying power.

Emulsification technology that does not use surfactants

Emulsification in common cosmetics requires surfactants to mix water and oil.

However, surfactants are also ingredients that are concerned about irritation to the skin and the effects of long-term use.

This technology uses the emulsifying effect of silk fibroin to achieve stable emulsification without the use of surfactants.

This enables formulations that are gentle on the skin and the development of cosmetics that can be used by more people with peace of mind.

Cosmetics production using reduced ionized water

“Reduced ionized water” that quickly penetrates the skin and gives it firmness

Reduced ionized water is an excellent material for adding new value to products. By taking advantage of its properties, such as high penetration power, moisturizing effect, and even anti-aging effect, we support competitive product development.

Point 1: No preservatives used

Reduced ion water has strong alkalinity and naturally inhibits the growth of bacteria. This property allows us to maintain product quality without the use of preservatives. Additionally, since it becomes slightly acidic when used, it is gentle on the skin and can increase the safety of the product.

Point 2: High penetration power

Reduced ionized water has a low surface tension and blends well into the skin, so it boasts higher penetrating power than purified water. This allows for more efficient moisturization and penetration of ingredients, maximizing the effectiveness of the product. The penetration power that cannot be achieved with purified water increases the appeal of the product.

Point 3: Emulsification effect

Since products can be made without using emulsifiers, it is possible to make natural products. However, you do need to shake it before use, but it requires less effort and gives a more natural finish.

Point 4: Reduction of oxidation (aging)

Reduced ionized water has the property of reducing oxidation and is effective in preventing product deterioration. For example, it has been confirmed that using reduced ionized water delays the oxidation of apples. By taking advantage of this property, it is possible to improve the shelf life of products and add anti-aging effects.

Product processing equipment/facilities

All equipment and facilities in-house

CHARITES LAB, we not only supply placenta raw materials manufactured in-house, but also manufacture cosmetics and food products using the placenta raw materials. Our factory handles everything from placenta raw materials to commercialization.

Placenta raw materials (placenta extract) extracted using a special manufacturing method at our own factory are supplied as raw materials, as well as after they have been commercialized into foods and cosmetics (creams, lotions, essences, etc.). In addition, as the placenta odor is reduced and the viscosity is lowered, the range of applications for products has been greatly expanded even when highly concentrated placenta raw materials are used.

Processing equipment for placenta powder products

We process the placenta raw material (extract) extracted in-house into powder.

We manufacture two types of powder, FD (freeze-dried) and SD (spray-dried), and use them to commercialize products. Products using placenta powder (FD, SD) are mainly used in health food products.

Freeze dry

Freeze dry

Powder Sterilization Equipment

capsule filling equipment

List of placenta available

Horse placenta

1. Placenta stock solution/horse for cosmetics (preservative: phenoxyethanol)

| Product name | Purpose | Display name | INCI name | Composition (%) | Essence | Function | Warranty period (Storage method) | Package presentation | Nitrogen amount (%) |

| placenta stock solution 10 specifications | cosmetics | placenta extract water phenoxyethanol | PLACENTAL PROTEIN WATER PHENOXYETHANOL | 14.4 84.9 0.7 | protein obtained from horse placenta | cell activation | 24 months (refrigerated) | 1kg | 1.0~1.19 |

| placenta stock solution 01 specifications | cosmetics | placenta extract water phenoxyethanol | PLACENTAL PROTEIN WATER PHENOXYETHANOL | 1.19 or less 98.11 0.70 | protein obtained from horse placenta | cell activation | 24 months (refrigerated) | 1kg | 0.1~0.19 |

2. Placenta stock solution/horse food use

| Product name | Purpose | Display name | Composition (%) | Essence | Function | Warranty period (Storage method) | Package presentation | Nitrogen amount (%) |

| placenta stock solution 10 specifications | food | placenta extract water | 14.4 85.6 | protein obtained from horse placenta | cell activation | 24 months (refrigerated) | 1kg | 1.0~1.19 |

| placenta stock solution 01 specifications | food | placenta extract water | 0.63 99.37 | protein obtained from horse placenta | cell activation | 24 months (refrigerated) | 20kg | 0.1~0.19 |

3. Placenta powder/Uma FD

| Product name | Purpose | Display name | Composition (%) | Essence | Function | Warranty period (Storage method) | Package presentation | Nitrogen amount (%) |

| placenta powder FD100 | food | placenta extract pure powder | 100 | protein obtained from horse placenta | moisturizing | 24 months (cool and dark place) | 1kg | 13.0~15.5 |

| placenta powder FD10 | food | placenta extract pure powder Indigestible dextrin (dietary fiber) | 10 90 | protein obtained from horse placenta | moisturizing | 24 months (cool and dark place) | 5kg | 1.5~2.5 |